SERIOLA 32 & 100

礦物基熱媒油使用290度C

SERIOLA 32 & 100

熱媒油

礦物基熱媒油

用途APPLICATIONS

- 推薦用在開放及封閉的熱媒交換系統

SERIOLA 32 and 100 are recommended for heat transfer installations using thermal fluid circulation, in open and closed circuits. - 特別適用於以下相關的工業別,加熱控制系統…

SERIOLA 32 and 100 are suitable for heating and temperature control in all industries, and particularly for following manufacturing processes:

- 蒸氣產業 Steam production

- 造紙業 Paper Industry

- 木材業 Timber Industry

- 紡織 Textile Industry

- 石油 & 天然氣 Oil & Gas

規格SPECIFICATIONS

國際標準

- ISO 674-12 L-QB-290 / DIN 51522 – class Q ISO 674-12 L-QB-290 / DIN 51522 – class Q

- SERIOLA 32 經法國健康部指定可使用於飲用水處理

SERIOLA 32 is approved by the French Health Direction for drinking water treatment.

優點ADVANTAGES

沉積少、溫度保持、壽命長Long life 、Low circuit deposits formation 、Slow warming time

- 比起傳統熱媒油有更佳的抗氧化性

Compared to conventional fluids, SERIOLA 32 and 100 deliver high oxisdation resistance thanks to a duly selected antioxidant.

- 在 340°C 的靜態及動態流體測驗中,沉積物的量,比傳統熱媒油更少, 時間拉長約 10~20 倍.低沸物的量減少約 50%

Static and dynamic deterioration tests have shown that at temperatures exceeding 340°C, deposit formation is 10 to 20 times lower than other mineral fluids and light fractions formation rate was reduced by 50%.

| 代表特性TYPICAL CHARACTERISTICS | 檢測法 METHODS | 單位 UNITS | SERIOLA 32 | SERIOLA 100 |

| 外觀 Appaerance | - | 目視 | 黃Yellow | 淡棕 Light Brown |

| 密度@ 15°C Density at 15°C | ISO 12185 | kg/m³ | 812 | 828 |

| 黏度@ 40 °C Kinematic Viscosity at 40°C | ISO 3104 | mm²/s | 32 | 95 |

| 流動點 Pour point | ISO 3016 | °C | -15 | -9 |

| Cleveland 閃火點(開杯式)Flash point – Open Cup | ISO 2592 | °C | 230 | 260 |

| Cleveland 閃火點(閉杯式)Flash point – Closed Cup | ISO 2719 | °C | 223 | >300 |

| Fire point | ISO 2592 | - | - | - |

| 初沸點 Initial Boiling Point | ASTM 2887 | °C | 260 | 290 |

| 終沸點 Final Boiling Point | ASTM 2887 | °C | 310 | 319 |

| 自燃點 Auto ignition temperature | ASTM E659 | °C | 549 | 615 |

| Conradson 殘碳量 Conradson carbon residue | ISO 6615 | % 重量 | <0.01 | <0.01 |

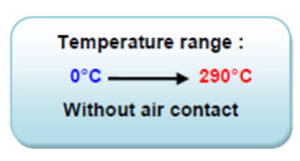

| 最低操作溫度 Minimal operating temperature | - | °C | 0 | 0 |

| 油心溫度極限* Maximum bulk temperature | GB/T 23800 | °C | 290 | 290 |

| 油膜極限溫度* Maximum film temperature | GB/T 23800 | °C | 310 | 310 |

* 未與空氣接觸

STORAGE RECOMMENDATIONS

- Store the product at ambient temperature

- Minimize the periods of exposure to temperatures above 35°C

- Shelf life : 5 years from date of manufacture (unopened)

請儲存於室溫的環境/ 盡量不可暴露於溫度>35°C/未開封可保存 5 年

Thermal conductivity:

熱導係數,此數值愈高,代表效率愈佳,需求使用較少的熱 Specific heat:比熱,流體儲存熱的能力,將 1 公克的流體,提升 1°C 所需的能源 property of a material to conduct heat. The higher thermal conductivity, the more efficient the heat transfer fluid will be. Less heat will be required.

Vapor pressure:

在一個封閉的系統中,利用流體熱力裝置加熱,因為固態或液態轉換成蒸氣所產生的壓力.在熱 媒油的操作上,此壓力愈低相對愈安全.

pressure exerted by a vapor in thermodynamic equilibrium with its condensed phases (solid or liquid) at a given temperature in a closed system. For a heat transfer fluid, a low vapor pressure is recommended to operate safely.

Enthalpy of vaporization:

將一定量的物質,由液態變成汽態所需的能量(火含)

amount of energy (enthalpy) that must be added to the liquid substance, to transform a quantity of that substance into a gas.

Thermal

Thermal conductivity:

熱導係數,此數值愈高,代表效率愈佳,需求使用較少的熱 Specific heat:比熱,流體儲存熱的能力,將 1 公克的流體,提升 1°C 所需的能源

property of a material to conduct heat. The higher thermal conductivity, the more efficient the heat transfer fluid will be. Less heat will be required.

Specific heat :

fluid’s ability to store the heat. It isdefined by the required energy to raise 1°C the temperature of 1 gram of a fluid.

Vapor pressure:

在一個封閉的系統中,利用流體熱力裝置加熱,因為固態或液態轉換成蒸氣所產生的壓力.在熱 媒油的操作上,此壓力愈低相對愈安全.

fluid’s ability to store the heat. It isdefined by the required energy to raise 1°C the temperature of 1 gram of a fluid.

Enthalpy of vaporization:

將一定量的物質,由液態變成汽態所需的能量(火含)

The enthalpy of vaporization :

amount of energy (enthalpy) that must be added to the liquid substance, to transform a quantity of that substance into a gas.

Thermal